When it comes time to decide whether to use graphite or copper electrodes in your shop, it’s important to look at the big picture. According to Stu Haley, regional manager of Madison Heights, MI-based Belmont Technologies, Inc., a provider of EDM supplies, tooling, accessories and machines, “To say which electrode works best is very difficult, it is totally applications-driven. So much depends on what you have to work with on your shop floor in the way of support equipment. Both copper and graphite provide approximately the same end result. The difference is time to EDM the work and electrode manufacturing time and cost.”

Haley explains that choosing an electrode material is often a result of where you were born and what type of EDM equipment you use. “For example, graphite was basically developed in the United States back in the early 1960s, so the American EDM equipment manufacturers in those days concentrated on the graphite circuitry when designing their equipment,” he says. “Whereas, since the European and Asian EDM equipment manufacturers didn’t have access to graphite, they developed copper circuitry.

“If you have newer equipment built after 1990, the electrode material of choice in North America is graphite,” he adds. “This is used in 90 percent of the applications. In Europe and Asia, graphite is becoming more popular as an electrode material because of availability, machinability, and speed of cutting.” Following are some of the advantages and disadvantages of each material so that you can decide which is best for your application.

Graphite

Advantages and Benefits

Sold by grades, graphite cuts approximately three times faster than copper, according to Haley. “What makes a good grade or a poor grade is particle size,” he explains. “Particle size gives you strength, machinability and greatly influences the metal removal rate, wear, and the surface finish. Graphite is made up of carbon particles that are put through a graphitizing process to produce graphite. The smaller the particle size is, the better the graphite. Particle sizes in different grades of graphite can be .0006″ for general-purpose use to .00004” for the extremely fine detail and superior surface finishes. Graphite can be purchased in big blocks, and then cut up to be machined, or it can be ordered precut or ground into the size you require.

“Graphite machines very easily – you can mill it, grind it, turn it, drill it, tap it, even file it to whatever shape you want,” Haley continues. “Another advantage of graphite is that it doesn’t burr. You can put it on a duplicating machine or a graphite high-speed mill and cut out complex shapes and forms, and once it’s cut you are finished – with no deburring.”

Limitations

If mold maker has the older fabricating equipment, machining graphite electrodes will result in dust particles on the shop floor and in the nearby machines. However, the new high-speed mills that are sold today are specially designed to machine graphite. “They are totally enclosed and have a vacuum system to remove all of the dust,” Haley points out, “and there are some machines that can even cut square internal corners.”

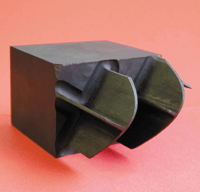

Copper

Advantages and Benefits

Haley notes that copper can be cut on wire EDM machines, but there are only certain graphites that can be cut on a wire machine – the particle size should be five microns or less. Copper also is a little more forgiving in a poor flush situation than graphite. “In EDM, if the flush doesn’t remove the eroded particles or chips out of the cutting area, there’s something that can occur where you get a non-pulsating, direct flow of current from the electrode to the workpiece,” Haley explains. “The result of this is a pit in the workpiece. Copper is more forgiving in those applications – all metallic electrodes are – they won’t arc out as fast. But some of the newer EDM power supplies have adaptive logic or fuzzy logic, which eliminates the problem altogether. Copper – when used in specific settings with the correct flushing techniques using a CNC machine or a machine with an orbiting system – can produce a mirror-like surface finish. This is useful in small cavities where it is difficult to polish.”

Limitations

“Copper is more difficult to machine,” says Haley, “and when you mill it, it has the tendency to stick to the cutter. When you grind it, it can clog up the grinding wheel – it heats up quickly and has a tendency to grab the grinding wheel. You’ll have burrs no matter how you machine it, so you have to deburr it. Size and weight also can be an issue. A 12″ x 7″ x 2 3/4” piece of copper weighs 75 pounds, whereas a piece of graphite the same size is 11 pounds.

“The bottom line uses what you think will work best in your shop with the equipment that you have available,” Haley continues. “If some electrodes are beyond your machining ability, have someone make them for you. You have to base it on your own experience and the resources you have available. Ask for suggestions from the equipment manufacturer or from your electrode material supplier. Regardless of what electrode material or combination of materials you decide on, be sure that you know the speeds and feeds to machine the material safely. When in doubt, ask.”

Article Resource: https://www.moldmakingtechnology.com/articles/using-copper-and-graphite-electrodes-look-at-the-big-picture