What is Plastic Injection Molding?

After the plastic material is heated and plasticized in the injection unit, which includes the hopper, barrel, and reciprocating screw, the molten plastic flow will be injected into the mold cavity through the sprue and runner system, and finally, take shape after being cooled. This manufacturing process is defined as plastic injection molding. The plastic injection molding process is efficient and complex, involving precise control over parameters to produce intricate parts quickly and cost-effectively. Custom injection molding is a versatile and essential service for producing plastic prototypes and on-demand parts with quick turnaround times. Custom plastic injection molding offers advantages such as rapid prototyping and expert engineering reviews, ensuring accurate quotes and high-quality results.

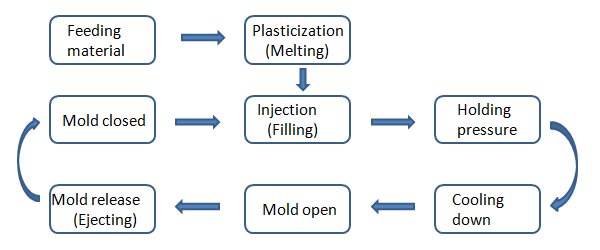

The Detail of The Process

During the molding process, the plastic pellets will be first delivered into the high-temperature injection barrel through the hopper, where they are heated, melted and plasticized into a sticky molten flow, which will then be injected into a lower temperature closed mold through the injection nozzle at a high speed under the great pushing pressure exerted by the plunger or the screw. Customers own their injection mold tools after production runs, and the importance of high-quality materials and expert craftsmanship in tool making cannot be overstated. The injection molding cycle, known for its rapid production capabilities, can take less than a minute, allowing for mass production of multiple parts. Controlling various parameters is crucial to ensure quality, and design choices like wall thickness can impact cycle time.

Under the great pressure, the melted plastic will fill the entire cavity and will also be compacted. After that, the plunger or the screw will return after a period of pressure holding. At this point, it is possible to flow back from the cavity into the sprue and runner system.

When the mold opens after cooling and forming, the product will be released from the mold cavity.

Pellets or powders are fed into the hopper.

The plastic is heated in the barrel and turned from solid pellets into a molten flow, which possesses great plasticity.

The plasticized molten flow will be pushed to the forepart of the barrel by the plunger or the screw, and then injected to fill the mold cavity through the injection nozzle and sprue & runner system of the mold. This step is called an injection.

When the molten material is shrinking inside the mold due to cooling, the plunger or the screw will continuously force the molten material in the barrel into the mold for replenishment, to ensure that a complete structured and the densely textured product is produced. This step is known as pressure holding.

The in-mold cooling process usually refers to the entire process from the moment the molten material at the gate is fully solidified to the plastic part is ejected from the mold cavity; but actually the cooling step starts the minute the molten plastic flows into the cavity, covering the time period from completion of the injection, pressure holding to the moment before mold release starts.

Mold release is allowed when is cooled to a certain temperature, through which the plastic part is pushed out of the mold by the ejectors.

The Key Parameters That Determine The Product Molding Quality Including:

- Mod temperature

- Injection Temperature

- Pressure

- Injection Speed

- Position

Our advanced production techniques ensure that injection molded parts are produced with precision and efficiency, meeting the high standards required for various applications, including the medical device sector.

Why Choosing Ecomolding For Plastic Injection Molding?

Injection molding process boasts a diversity of advantages, among which the most significant ones are shown below:

Having a reliable injection molding partner is crucial for ensuring timely deliveries and maintaining high-quality standards. Ecomolding is committed to managing transitions smoothly and delivering exceptional results for clients. Injection molding allows for the mass production of identical parts efficiently and cost-effectively.

The injection molding service provided by Ecomolding is able to be fully automated to realize high production efficiency. The service ensures the production of immensely detailed or complicatedly designed plastic injection molded parts. What you need is an engineering design company or an internal design department to develop great designs. Yet, the moment apart is the manufacturing process, there would be little finishing work needing to be done because the produced parts look extremely finished. Ecomolding’s injection molding service is ISO certified, offering quick turnaround times and customizations tailored to client needs, ensuring efficient and high-quality manufacturing processes.

To gain the desired material properties in your final products, you are allowed to select a wide range of materials in the process or mix different materials for a combined outcome. The combined use of more than 1 material (usually 2 different materials) is referred to as co-injection molding. Generally speaking, very little waste will be produced in the injection molding process, because excessive materials are able to be easily recycled.

Mold inserts can be used to produce a new part (through this process, you can change the internal cavity without complete redesigning or re-machining of the steel or aluminum tools by CNC). Apparently, the life cycle of the tooling will be dependent on the injection molding materials, and particularly on the geometry of the part and the barrel temperature of the materials. To be specific, high temperatures and delicate (thin) geometric shapes will shorten the service life of the tooling.

However, the injection molding process also has some distinct disadvantages. For example, the tooling costs are too high that it is not easy for average independent designers to reach them. Keep this in mind, you will know how to choose the alternatives.

What Kinds of Material We Use For?

It is an important decision for you to choose the proper plastic materials for your customized injection molding project. You have to consider multiple factors before selecting the right materials, such as part application, function, flexibility, durability, and color. Different plastic molding materials look and behave differently, so the materials you choose will have a direct influence on your products’ performance and features. You even need to consider the material’s shrinkage rate. Liquid silicone rubber is an excellent choice for creating flexible and durable parts, especially in thermoset applications where a two-component compound is mixed and heat-cured in a mold.

The role of plastic resin in the injection molding process is crucial, as it can be either virgin or recycled material that is heated and transformed into a semi-liquid state for efficient injection into mold cavities. The quality of the plastic resin directly impacts the finish and dimensional tolerances of the molded parts, as well as production costs and efficiency.

If a plastic injection molded part is made out of a single material for the initial production run, the part dimensions may be affected if you change the material for future productions. This is because different materials show different shrinkage performance. Liquid silicone rubber molding is a thermoset manufacturing process that involves mixing a two-component compound, which is subsequently heat-cured in a mold with a platinum catalyst. This process is ideal for creating custom silicone prototypes and production parts, offering versatility and rapid turnaround times.

ECO Molding offers a wide range of plastic materials to be used for the process. We will also welcome you if you make requests for special resin materials. However, if what you need is not included in the list, please don’t hesitate to contact us and we will do what we can to meet your personalized material needs. the material we often use as below: ABS,PA6,PA66,PP,PC,PC/ABS,PS,POM,PPS and so on.

Company Capbility

Eco Molding co., Ltd is one of the more well-known injection molding companies in China. Our factory is equipped with 20 sets of high precision injection molding machines, ranging from 50 tons to 650 tons. They are mostly imported from Taiwan and Japan, our injection shop runs 24 hours a day, 7 days a week, and provides production services. We also specialize in insert molding, which is crucial for creating strong and functional prototypes and production parts.

The role of plastic parts in various industries, such as automotive, consumer products, and electronics, is significant. Injection molding technology enables the efficient and cost-effective mass production of high volumes of identical plastic parts.

We are experienced with various plastic products for many industries, including automotive, medical, lighting, sports equipment, home appliances, and agriculture. Our expertise in producing high-quality molded parts ensures rapid turnaround times and cost-effectiveness for diverse production needs. We are an accredited and ISO9001-2008 company since 2004. We also have 5 IPQC people constantly watching our production and checking the part quality. This ensures our production maintains the highest level of quality. In the last 15 years, Eco Mold has established a strong reputation for producing high-quality tools and parts at a reasonable price. We maintain strong business relationships with approximately 50 customers, mainly from the USA and Europe.

The complexity of plastic injection molds requires the selection of appropriate thermoplastics and effective mold design. Experienced engineers are essential for creating molds that can withstand high pressures and temperatures during the manufacturing process. Additionally, our focus on production tooling is a critical aspect of our successful manufacturing and product development, offering durability and capability for high-volume production.

FAQs

When the machine first starts, the melting in the injection molding machine barrel flows smoothly with a lower stickiness thanks to a longer period of heating, so product burrs tend to occur. After a while of production, since the melting continuously takes the heat away, the product will not be fully injected due to great stickiness and poor liquidity. This problem can be solved by gradually increasing the temperature of the barrel after some time into the production.

In the production process, the melting continuously takes the heat away, so the product will not be fully injected due to great stickiness and poor liquidity. This problem can be solved by increasing the temperature of the injection molding machine barrel.

A product becomes oval is because the melting is not evenly fed, causing uneven pressure on the circumference of the product thus making it oval. The 3-point injection approach can be adapted to allow for even feeding.

Want to Start Injection Mold Project Today?

We offer high standard injection molding services, support low volume manufacturing, fast delivery, and quick respond within 24 hours.