Injection Molding Lifter: The Design Standard for Plastic Mold Tooling

Injection Molding Lifter Design in Plastic Injection Mold Tooling The lifter is mainly used to form the internal undercuts of an injection molded plastic part, and at the same time it also offers ejection function. Considerations in lifter design include selecting abrasion-resistant and durable materials to withstand pressures and ensure operational efficiency. Ejector pins are essential for pushing molded parts out when the mold opens, particularly in scenarios with undercuts. The ejector plate moves upward to assist lifters during the ejection process, allowing molded products to be effectively released from the mold. Complex mold design is crucial as it directly impacts the injection molding machine’s lifter mechanism, especially when dealing with intricate product features like undercuts. The mold cavity plays … Read more

Pantone Color Chart: The Matching System Guide

The Pantone Color Matching System is largely a standardized color reproduction system, providing resources and tools for accurately identifying and matching colors in design and printing. The importance of colour in customizing products and ensuring brand representation cannot be overstated. By standardizing the colors, different manufacturers in different locations can all refer to the Pantone system to make sure colors match without direct contact with one another. This collaboration with clients across various creative disciplines and marketplaces showcases the global reach and expertise in providing color insights and solutions tailored to meet the specific needs of these clients. Selecting the right colours in graphic design and printing is crucial, and the Pantone Matching System is an essential resource for this … Read more

What Causes Black Marks on Plastic? Understanding Specks/Streaks in Injection Molding Parts

Black specks/streaks and impurities are the most important factors that lead to rejects in the normal production process. Stubborn stains mainly affect the appearance of the product and lead to scrap. Most of the impurities and black specks are usually caused by foreign substances, i.e., they have nothing to do with the raw material itself. Only a small portion of the black specks and impurities are caused by the raw material itself. Black specks and impurities are characterized by small dark brown particles, which generally do not reflect light. When the particles are large, the impurities are layered, brittle, fragile and porous after being broken. Some of them are irregularly scattered on the whole, some are scattered randomly in … Read more

Injection Molding Defects Causes and Remedies PDF: A Guide to Countermeasures

April 6, 2018 The causes and countermeasures described below are aimed to solve the common injection molding defects that might occur in ordinary circumstances. The examples are just based on my own personal work experience, so if there is anything inappropriate, you are welcome to correct me! Short shots (incomplete filling) – injection molding defects (1) Short shots (incomplete filling): The molten plastic fails to fill up each and every corner in the entire mold cavity. (2) Causes and Countermeasures Flash (1) Flash: Excess material in the form of extra plastic, such as films or burrs, which appears on the parting surface, around the runner, or in the insert crevice. (2) Causes & Countermeasures (See the table below) *Note: Flash also … Read more

Holding Pressure in Injection Moulding: What is it and How to Set it?

The setting of hold pressure is aimed to prevent resin backflow, while at the same time compensating for resin shrinkage caused during the cooling process, so as to achieve the optimal molding outcome. If the holding pressure is set too high, the product will be prone to flash, over filling or stress concentrating near the gate, etc.; on the other hand, if the holding pressure is too low, excessive shrinkage and dimensional instability will be likely to occur. Initial injection pressure helps in filling the mold cavity, while holding pressure is crucial for maintaining part quality and preventing shrinkage. Back pressure is also important in ensuring consistent mixing of resin and maintaining part quality, as well as controlling the movement … Read more

What causes silver streaks or marks during injection molding?

Definition of silver Streaks: Silver streaks are also referred to as silver marks, which appear like burst blisters on the surface of injection molded parts, mostly in the shape arrows pointing to the gate. Causes of Silver Streaks: I. Equipment 1. The nozzle hole is too small, the material leaks or draws at the nozzle, or the barrel or the nozzle is obstructed, and the material decomposes due to the frictional heat caused by high-speed melt flow; 2. The barrel and the screw wear, or melt flow dead ends exist in the screw cap and collar, which are decomposed due to long-time heating. 3. The heating system is out of control, causing the temperature to be too high and resulting … Read more

What Causes Part Crack in Plastic Injection Molded Parts

Cracks are a commonly seen defect in plastic injection molded products, of which the main causes are stress and deformation, mainly including residual stress, external stress and product deformation caused by external environment. (I) Cracking caused by residue stress The residual stress is mainly generated in the following three scenarios, i.e., overfilling, product ejection and metal inserts. The cracking generated in the case of overfilling can be solved from the following aspects: (1) Since the direct gate is able to minimize pressure loss, if cracking is mainly generated around the direct gate, you can opt for the multi-point gate, the side gate or the tab gate. (2) On condition that the resin material does not decompose or deteriorate, appropriately increasing … Read more

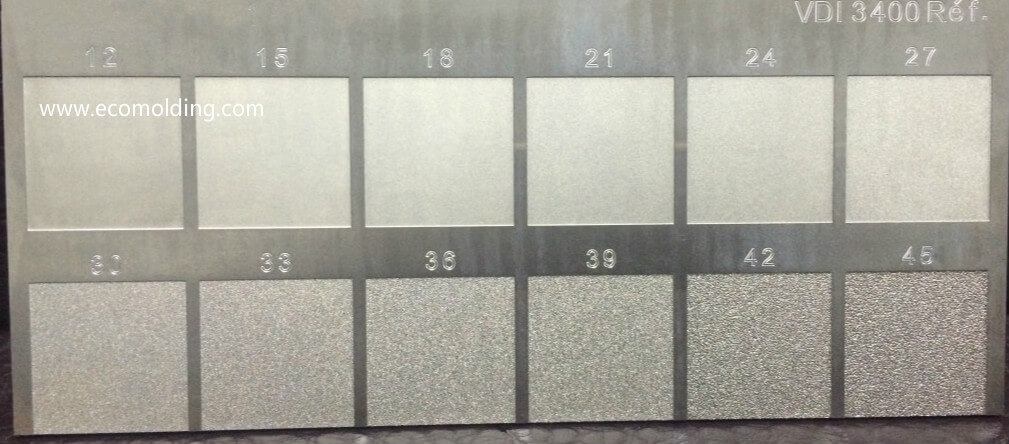

VDI 3400 Mold Texture and Drafting Angle

Bayer Plastics has some good Information about surfaces and injection molding available on their web- Site. According to a (German) Document the VDI 3400 texture surfaces correspond to the following Ra / Rz Values and require the following drafting angles: VDI 3400 defines surface texture standards for mold-making. It categorizes roughness classes using Ra values. German engineers played a crucial role in developing the VDI 3400 standard, ensuring consistent texture quality and improving product performance. VDI3400RaRzDA-PADA-PCDA-ABS120.40 1.50 0.5 1.0 0.5 150.56 2.40 0.5 1.0 0.5 180.80 3.30 0.5 1.0 0.5 211.12 4.70 0.5 1.0 0.5 241.60 6.50 0.5 1.5 1.0 272.24 10.50 1.0 2.0 1.5 303.15 12.50 1.5 2.0 2.0 334.50 17.50 2.0 3.0 2.5 366.30 24.00 2.5 4.0 3.0 … Read more

PMMA acrylic injection Molding Defect Causes and Solutions

The defects in the injection molding of acrylic PMMA usually include: short shot, silver streaks, sink marks, voids, jetting, weld marks, gray / black specks, cracking, warpage, and material impurity, while the preventive measures against them are usually: Short Shot This is caused because the resin does not fill the cavity fully. To prevent its occurrence, we can take the following measures: 1. Adjust the supply quantity of acrylic pellets 2. Increase the injection pressure 3. Increase the injection speed 4. Raise the barrel temperature 5. Increase the screw backpressure 6. Raise the mold temperature for molding of thin-walled products 7. Extend the pressure holding time during injection 8. Extend the molding cycle 9. Increase the cross-sectional area of the … Read more

Plastic annealing and Moisture conditioning process for plastic product

Plastic annealing process The purpose of plastic annealing is to eliminate internal stress. For example, in the area where the thin and thick parts meet, the cooling of the thick part is slower than that of the thin part, causing the joint to shrink unevenly. As a result, there is stress concentration in the area. This phenomenon is more obvious around metal inserts. If annealing is not performed, cracking or even deformation may occur in the stress concentration area after a period of time. Annealing method: Usually, the product is immersed in hot oil, hot water, or cycling hot air. The annealing temperature is adjusted according to the type of the plastic, but usually, it is 10-20°C lower than the … Read more