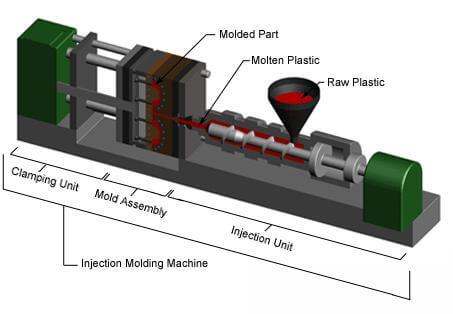

Injection molding is the most commonly used manufacturing process for the fabrication of plastic pieces. A wide variety of products are manufactured using injection molding, which varies greatly in their size, complexity, and application. The injection molding process requires the use of an injection molding machine, raw plastic material, and a mold. The plastic is melted in the injection molding machine and then injected into the mold, where it cools and solidifies into the final part. The steps in this process are described in greater detail in the next section.

Plastic parts are used in a variety of products including home appliances, consumer electronics, power tools, and as automotive dashboards. Other common thin-walled products include different types of open containers, such as buckets. Injection molding is also used to produce several everyday items such as toothbrushes or small plastic toys. Many medical devices, including valves and syringes, are manufactured using injection molding as well.

the plastic parts have many advantages compare to metal parts, glass, wood.such as lightweight, cheaper price, and the cycle of production will be shorter the different hardness and chemical stability. and better insulation performance.