Ejector pin marks usually refer to the glossy or white imprints on the surface of a injection molded product, as well as the different levels of glossiness – dark or shadow, without convex or concave – visible directly opposite to the ejector pin location. Factors that cause ejector pin mark 1. Product design: Inappropriate product … Read more

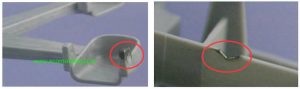

The causes of parts sticking and sprue sticking are multifaceted, among which mold failure is one of the main reasons. The reasons and corresponding solutions are described as follows: 1. The surface of the mold cavity and sprue bush is rough. If there are surface defects such as gouges, nicks, scars, and dents in the … Read more

Jetting, also known as jet, worm track, or snake-like pattern, refers to the snake-like curves on a plastic injection molded part along the flow direction from the gate, as shown in Figure 1. Under normal circumstances, the molten plastic fills the mold cavity in a “fountain flow” manner, as shown in Figure 2, which depicts … Read more

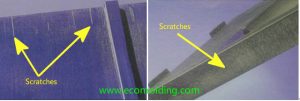

The scratches (scrape marks)on the appearance of an injection molded product usually occur on such deep-cavity products as chargers, routers, and chassis, etc. It is also a particularly common problem during the injection molding process, known as one of the 10 most challenging problems in the mold and injection molding industry. Glossy products, as well as … Read more

The definition of weld lines: When multiple plastic flow fronts meet in the cavity after encountering inserts, holes, or areas with inconsistent flow rates or interrupted melt flows, or in the case of gate injection filling, the inability of two or more flow fronts to fully “knit” together will cause the linear weld marks. The … Read more

Factor 1: Melt fracture causes burn marks When the melt is injected into a large-sized mold cavity under high-speed and high-pressure conditions, melt fracture will be easily caused. At this point of time, the surface of the melt is laterally fractured, with the fracture area coarsely mixed to form burn marks on the surface of … Read more

When compared with other tools, the plastic injection mold is more complicated and precise, with higher requirements for operation and maintenance. As a result, throughout the entire production process, their correct use and meticulous mold maintenance are of great significance to maintain the normal production and improve the efficiency of a company. 1. Select the … Read more

Short shot refers to incomplete filling of a mold cavity which results in the production of an incomplete part due to the insufficient plastic fluidity. The main causes are the inappropriate injection pressure and speed (including excessive pressure loss caused by resistance), which are mainly affected by the following aspects: I. Injection Molding Machine: (1) … Read more

Definition of Flow Lines: Flow lines, also known as flow marks Linear marks on the surface of a molded product, which indicates the flow direction of the molten plastic. Injection Molding process 1.Insufficient Pressure … Read more

According to the cause of air bubbles or vacuum voids , the solutions to the defects are described as below: (1) When the wall thickness of the product is large, the outer surface is cooled down faster than the center portion. Therefore, as the cooling progresses, the resin at the center portion is expanded toward … Read more