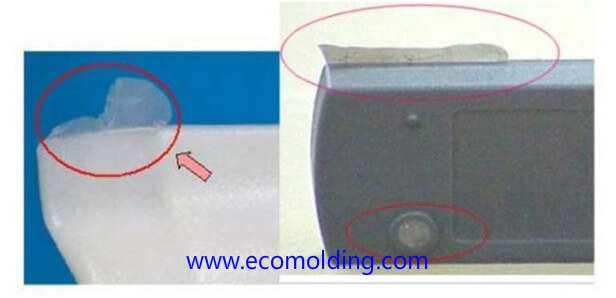

Flash, also known as flashing or burrs, mostly occurs between the matching parts of a mold, such as the parting surface of the mold, the sliding part of the slider, the clearance of the insert, and the gap of the ejector, etc. If the flashing is not resolved in a timely manner, it will be further worsened, so that the mold will be pressed to cause local collapses or other permanent damages. The flashing occurring in the clearance of the insert and the gap of the ejector will also cause the product to stick on the mold, thus affecting ejection.

Flash is actually the excessive plastic material which enters the matching gaps of the mold and is attached to the final product after cooling. It is very easy to solve the problem of flashing, i.e., keeping the melt out of the matching gaps in a mold. The plastic melt usually enters the mold matching gaps in two scenarios: one is that the mold matching gap is large, making it easy for the melt to get in; the other is that the mold matching gaps are not large at all, but the melt forces its way in due to high pressure. Seemingly, flashing can be completely solved by enhancing the manufacturing precision and the strength of the mold. Surely, it is necessary to improve the manufacturing precision, and reduce the matching clearance of the mold, so as to prevent the molten plastic from entering the gaps. However, the strength of the mold, in many cases, cannot be infinitely strengthened to keep the melt out under any pressure conditions.

The flash problem lies not only in production, but also in the process. To check the process, first check whether the clamping force is sufficient, and only check the mold itself if flashing still occurs after sufficient clamping force is ensured.

Ways to check if the clamping force is sufficient:

1). Gradually increase the injection pressure. If flashing increases as the pressure goes higher, and the flashing mainly occurs on the mold parting surface, it indicates that the clamping force is insufficient.

2). Gradually increase the clamping force of the injection molding machine. If the flash on the parting surface disappears when the clamping force reaches a certain value, or the flashing on the parting surface no longer worsens when the injection pressure is increased, it is considered that the clamping force is sufficient.

Ways to check if flash is caused by problems lying in mold precision:

Fill the mold cavity just right with a low material temperature, a low injection speed, and a low injection pressure (the product may shrink slightly). At this point of time, it can be considered that the melt is not very likely to enter the mold matching gaps. So, if flashing occurs, it can be determined that the mold manufacturing precision is problematic, thus mold repair is needed. You can give up the idea of solving the flashing issue by looking into the process.

It should be noted that the above-mentioned three “low” conditions are indispensable, as high melt temperature, fast injection speed, and high injection pressure will lead to partial pressure increase in the mold cavity, which may help the melt enter the mold matching gaps. As a result, the mold is forced open, though the cavity is not fully filled at the moment.

The causes of flash are to be analyzed on condition that the clamping force is high enough. If the clamping force is insufficient, it is difficult to analyze the reason for flashing. So, please be aware that the following analysis is based on the assumption that the clamping force is sufficient.