April 6, 2018

The causes and countermeasures described below are aimed to solve the common injection molding defects that might occur in ordinary circumstances. The examples are just based on my own personal work experience, so if there is anything inappropriate, you are welcome to correct me!

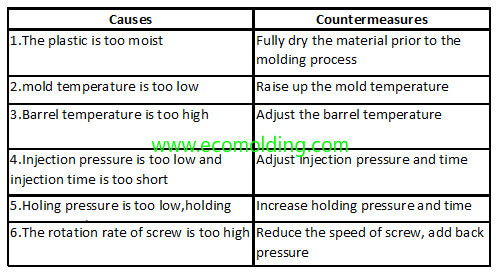

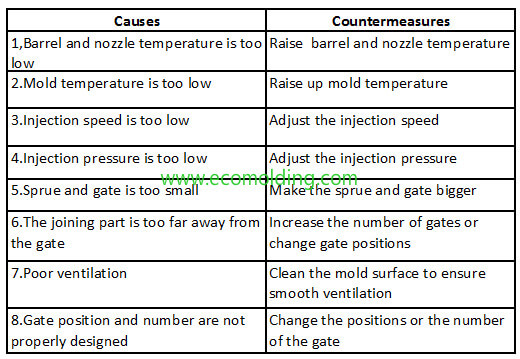

Short shots (incomplete filling) – injection molding defects

(1) Short shots (incomplete filling): The molten plastic fails to fill up each and every corner in the entire mold cavity.

(2) Causes and Countermeasures

Flash

(1) Flash: Excess material in the form of extra plastic, such as films or burrs, which appears on the parting surface, around the runner, or in the insert crevice.

(2) Causes & Countermeasures (See the table below)

*Note: Flash also tends to occur when the injection pressure/speed are too high, but molding time is too long and mold temperature is too low.

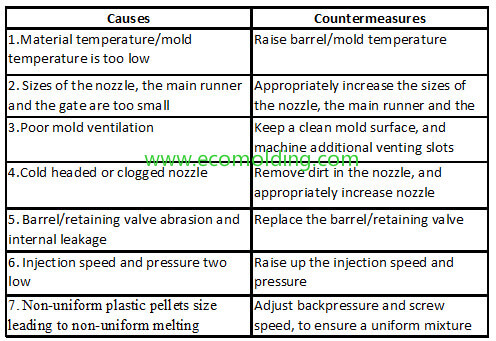

Silver streaks

(1) Silver streaks (silver lines) and flow lines: The radial silver white streaks on or around the product surface, which is formed along the plastic flow direction.

(2) Causes & Countermeasures (See the table below)

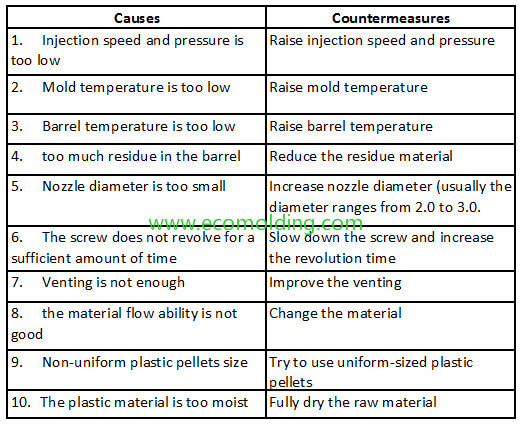

Low product glossiness

(1) Low product glossiness means the surface glossiness of the product does not meet the quality standard – the surface is not dioptric.

(2) Causes & Countermeasures (See the table below

Deformation due to mold temperature

(1)Deformation includes diagonal twists and warpage along parallel edges, often caused by poor material flow. They are the irregular curves that occur in the plastic injection molding process.

(2)Causes & Countermeasures (See the table below)

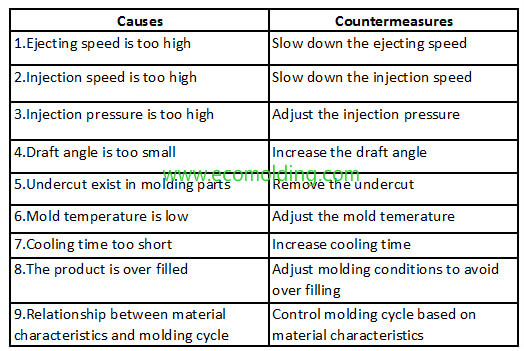

Ejecting marks

(1) Ejecting marks (AKA white marks): The white marks that occur in the ejector pin or other ejecting positions during mold release are often related to the injection process, including factors like speed and pressure.

(2) Causes & Countermeasures (See the table below)

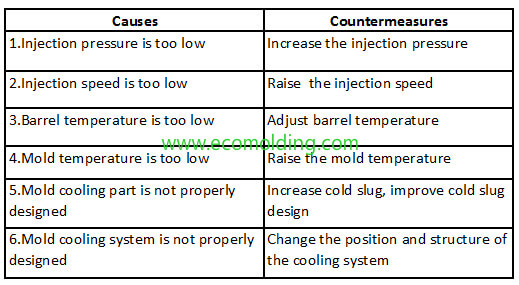

Weld lines

(1) Weld lines: The thin lines that occur when 2 or more molten materials are fusing in the plastic injection molding process, commonly seen in injection molded parts.

(2) Causes & Countermeasures (See the table below)

Jetting marks caused by injection speed

(1) Jetting marks: The streaks that the molten plastic produces around the gate can be influenced by improper melt temperature.

(2) Causes and Countermeasures

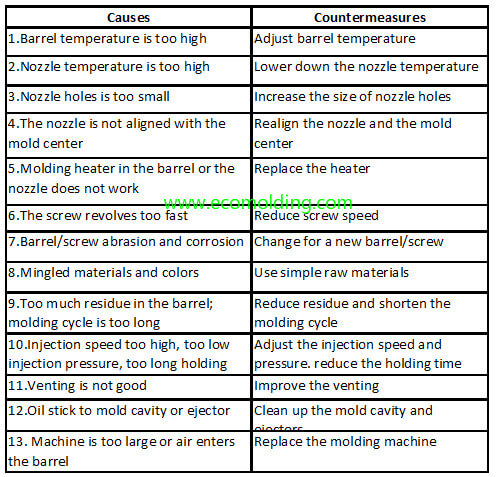

Discoloration (black marks)

(1) Discoloration (black marks): The black marks or other dark marks that appear on the product surface during the plastic injection molding production process.

(2) Causes & Countermeasures (See the table below)

Bubbles

(1) Bubbles: The residual voids sealed up in the product, which are caused by the evaporation of the moist contained in the molten plastic. Ensuring uniform wall thickness in part design can help prevent these bubbles by optimizing material flow and reducing common manufacturing defects.

(2) Causes & Countermeasures (See the table below)