Seven Common Defects and Solutions for PC/ABS injection molding Products

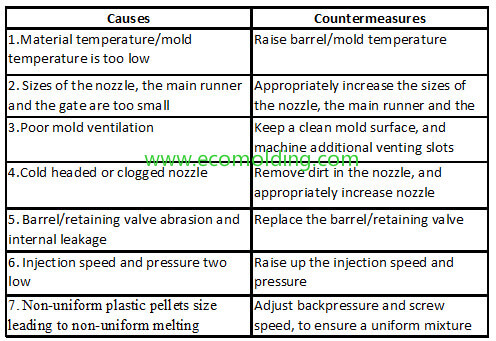

Flow Lines

The flow lines are caused due to the poor fluidity of the material. Unlike silver streaks, it is not caused by moisture or material decomposition, thus resulting in a different look.

Solution: The flow lines can be eliminated by raising the material temperature so as to improve the fluidity. Appropriate increase of mold temperature and decrease of injection speed can also solve the problem.

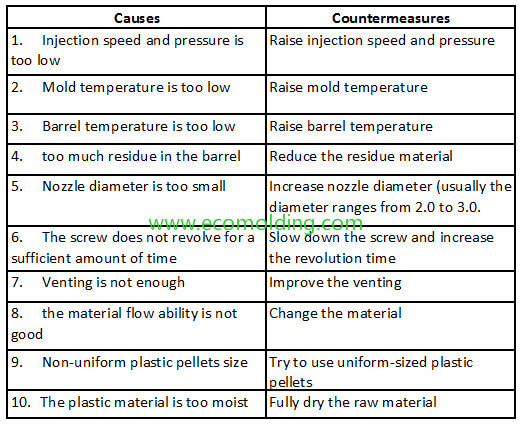

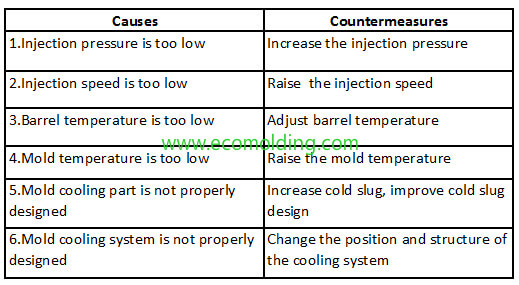

Pitting

The shrinkage cavities are caused by short shot in the mold cavity.

Solution: Increase mold temperature and material temperature appropriately to improve material fluidity; extend the injection / pressure holding time, and raise the injection speed to improve the mold filling, or increase the size of the gate and heat the sprue to reduce and eliminate the shrinkage cavities on the products.

If the product is not appropriately designed and the material temperature is too low, not only the shrinkage cavities, but also pitting will occur. If the material temperature and the mold temperature are too high, the melt will shrink excessively during cooling, resulting in pitting.

Solution: Appropriately increase the injection speed.

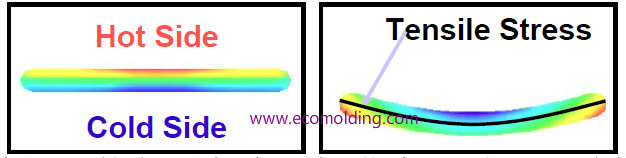

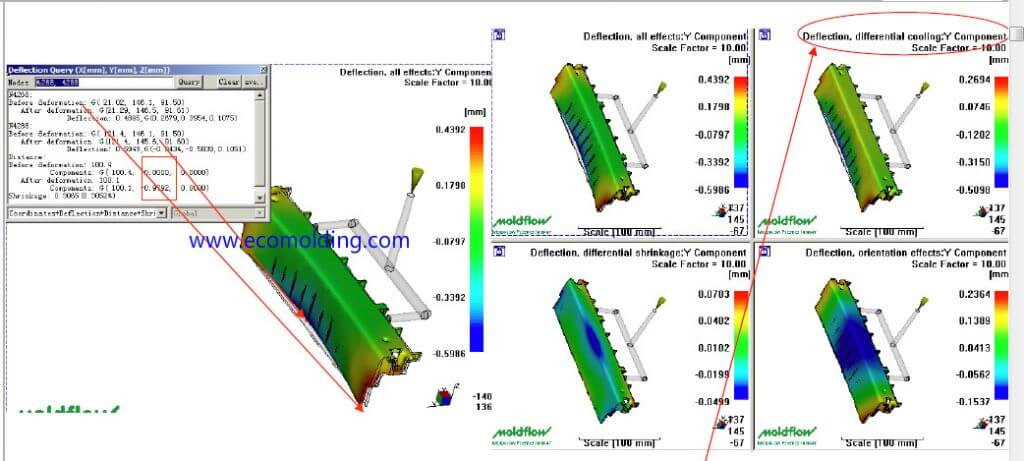

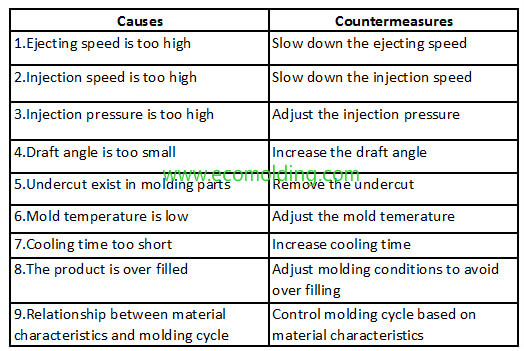

Warpage / Deformation

Solution:

The warpage / deformation of PC/ABS injection molding product is caused by the unreasonable product design, the improper gate location and the inappropriate conditions of the injection molding process, so that the stress is generated inside, leading to the ununiform or excessive shrinkage. If the mold temperature is too high or uneven, it will cause the difficult product ejection, or ununiform cooling, which will also lead to warpage / deformation.

Solution:

Molding Process: Extend the injection molding cycle, lower the injection molding temperature, appropriately adjust the injection pressure and the injection speed, reduce the ejection speed, increase the ejection area, and balance the ejector force.

Product Design: Increase product wall thickness, add ribs and fillet reinforcements to reduce warpage / deformation.

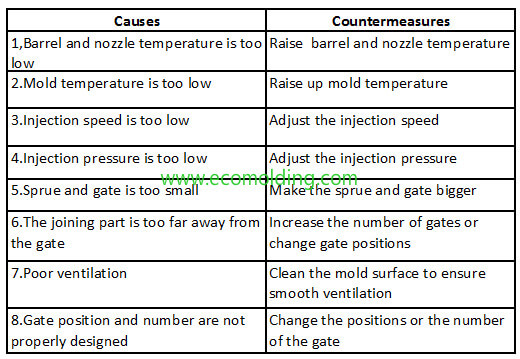

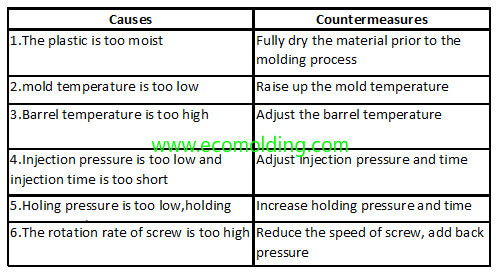

Silver Streaks

Silver streaks are the most common defects with the PC/ABS injection molding material, which refers to the appearance of the silvery-white silk-like stripes on the surface of the molded product along the flow direction.

The main cause is the interference of gas, which is mainly comprised of three components:

Air: The air drawn in during the melting and injection stages;

Moisture: The moisture contained in the material itself;

Pyrolysis Gas: Gas generated by high temperature hydrolysis / thermal decomposition.

Solution: First of all, check whether the material is fully dried; after the material is confirmed to be dry, the silver streak defect can be improved by adjusting the injection molding process. At the same time, this defect is also correlated to mold venting.

Matting

Solution:

Poor dispersion: add dispersant or oil, raise temperature, and increase backpressure.

Pay attention to the mold problem. Try some other materials.

Whether the injection temperature and time are sufficient.

Adjust the mold temperature.

Product Delamination

The delamination defect of PC/ABS injection molding products is closely related to the rupture of the melt caused by high shear force. Under low shear stress or velocity conditions, small disturbances caused by various factors are suppressed by the melt, while at high shear stress or velocity, disturbances in the melt are difficult to suppress and thus develop into an unstable flow;

When a critical shear force is reached, the fracture of the fluid will be caused.

Solution:

Material: The two components of PC and ABS are partially compatible, so it is necessary to add proper compatibilizer to improve the compatibility of the two components in the process of modification. Of course, the first thing to do is to eliminate the delamination caused by the mixture.

Mold: The principle of mold design should follow the direction of minimizing shear. Generally speaking, products with densely striped surfaces are more prone to delamination (caused by the friction shear between melt and inner wall of cavity during high-speed filling). At the same time, the gate size designed too small will lead to excessive shear when the melt is flowing through the gate, and then lead to product surface delamination.

Injection Molding Process: The main purpose is to avoid excessive shear. The high-speed & high-pressure injection can be used to improve the product filling difficulty, and therefore, in the actual injection molding process, the flow resistance in the actual filling process can be reduced, so as to avoid excessive shear caused by high-speed and high-pressure injection molding process

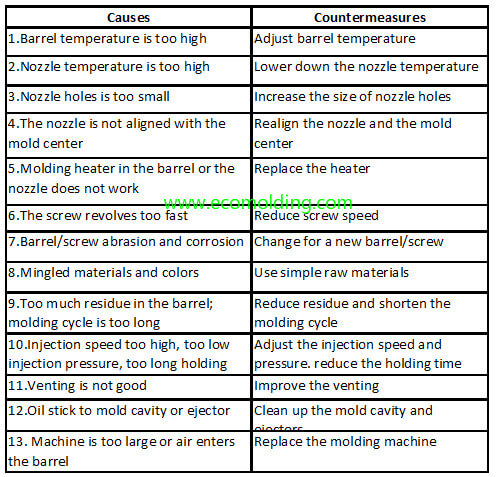

Stretch Marks

Stretch marks usually occur due to melt rupture when the melt expands into the mold cavity during high-speed injection.

Solution:

Molding Process: This defect can be reduced by raising the material temperature and the nozzle temperature, and slowing down the injection speed, etc.