Factor 1: Melt fracture causes burn marks

When the melt is injected into a large-sized mold cavity under high-speed and high-pressure conditions, melt fracture will be easily caused. At this point of time, the surface of the melt is laterally fractured, with the fracture area coarsely mixed to form burn marks on the surface of the plastic part. In particular, when a small amount of molten plastic is directly injected into an oversized mold cavity, melt fracture will be more serious, leaving larger burn marks on the product surface.

In essence, melt fracture is caused due to the elastic behavior of the polymer melt. When the melt flows into the barrel, the melt close to the barrel is rubbed by the wall of the barrel, resulting in higher stress and lower melt flow rate. The moment the melt is injected from the nozzle, the stress from the pipe wall disappears. The melt flow rate in the center of the barrel is extremely high, so the melt close to the wall of the barrel is accelerated by the melt in the center. Since the flow of the melt is relatively continuous, the melt flow velocity in the center and close to the wall will be rearranged, tending to the average speed.

During this process, a sharp stress change in the melt will cause strain. Since the injection speed is extremely fast, the stress is particularly high, much higher than the strain capacity of the melt, thus resulting in melt fracture.

When the melt encounters a sudden shape change in the runner, such as diameter shrinkage, expansion, and dead angle, the melt stays and circulates at the dead corner, so its stress is different from that of the normal melt, leading to larger shear deformation. When injected after being mixed with the normal flow, the recovery after deformation of the two is inconsistent and cannot be bridged. If the disparity is large, the fracture will be caused, i.e., melt fracture.

So, it is necessary to solve the melt fracture to eliminate burn marks:

- Eliminate the dead angle in the runner and make it as streamlined as possible;

- Appropriately raise the material temperature, reduce the melt relaxation time, and make it easy to recover from deformation and bridge the inconsistency;

- Add low molecular-weight polymers to the raw material, because the lower the molecular weight of the melt, the wider the distribution, and the more helpful to reduce the elastic effect;

- Properly control the injection and the screw speeds;

- It is very important to select the gate location and the gate type reasonably. It is proved that the enlarged pinpoint gate and the submarine gate (tunnel gate) are the ideal choices. With regard to gate location, it is preferable to ensure that the molten material is first injected into a transition cavity and then the large-sized cavity. Do not allow the melt to flow into the large cavity directly.

Factor 2: Molding conditions are not appropriately controlled

This is another important cause of charring and burns marks on the surface of a plastic product. In particular, the injection speed has a great influence on it. When the melt is slowly injected into the cavity, the flow state of the melt is laminar; when the injection speed gradually increases to a certain value, the flow state gradually becomes turbulent.

Generally speaking, the surface of the plastic part formed by laminar flow is relatively glossy and flat, while that formed under turbulent flow conditions are prone to burn marks on the surface, as well as pores inside. As a result, the injection speed should not be too high, and the flow should be controlled in a laminar state.

If the melt temperature is too high, the melt is easy to decompose and coke, resulting in burn marks on the surface of the plastic product. Usually, the screw speed of the injection molding machine should be lower than 90rpm, and the backpressure lower than 2mpa, so as to avoid excessive frictional heat generated inside the barrel.

If excessive frictional heat is generated due to the excessively long rotation time when the screw returns during the plastic injection molding process, the screw speed can be appropriately increased, the molding cycle can be appropriately extended, the screw back pressure can be appropriately lowered, the temperature of the barrel feeding section can be appropriately increased, and the raw materials with poor lubricity can be used to solve the issue.

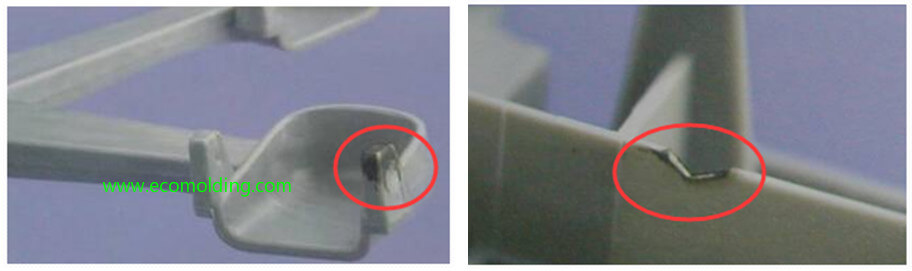

During the plastic injection molding process, the melt will depolymerize and decompose if the melt reflows too much along the screw channel, with resin staying at the anti-reverse ring. In this regard, the resin with a higher viscosity should be selected, the injection pressure should be appropriately lowered, and the injection molding machine with a relatively long diameter should be used. The anti-reverse ring commonly used in an injection molding machine is relatively easier to cause retention, causing the melt to decompose and discolor. When the decomposed and discolored molten material is injected into the cavity, brown or black burn marks is formed. In response, the nozzle-centric screw system should be cleaned regularly.

Factor 3: Mold failure

When the mold vents are blocked by the release agents and the solids deposited by the raw material, or the mold venting capacity or location are not properly designed, or the mold filling speed is too fast, the gas trapped in the mold will generate high temperature to burn the resin due to adiabatic compression. In response, the obstruction should be removed, the clamping force should be lowered, and mold venting improved.

The type and location of the mold gate are also very important considerations. The flow state of the melt and the venting performance of the mold should be fully considered in the design stage.

In addition, use an appropriate dose of release agent, and maintain a high glossiness of the cavity surface.

Factor 4: The raw material doesn’t meet requirements

If the raw material contains too much moisture and volatile contents, or the melt index is too high, or excessive lubricant is employed, charring and burn marks will be very likely to occur.

In response, treat the raw material with the hopper dryer or other pre-drying methods, select the resin with a smaller melt index, or reduce the amount of lubricant.