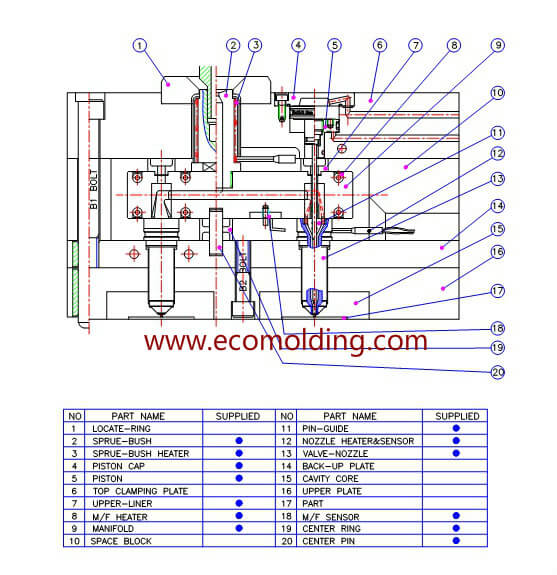

How the Hot Runner Systems Works

The cold runner of a plastic injection mold refers to the section between the mold inlet and the gate. The molten plastic maintains its fluidity inside the runner by virtue of the injection pressure and its own heat. However, as a part of the molding material, the runner is not a product. As a result, when designing a mold, we need to consider not only the filling effects, but also the material-saving effect produced by shortening or downsizing the runner; but in actuality, it is not easy for us to have the best of both worlds.

Types & Application of Hot Runners

When applying the hot runner technology, the proper selection of gate type is of critical importance, because gate type directly determines the selection of hot runner components as well as manufacturing and application of molds. Therefore, the hot runner system can be classified into 3 types based on the gate type, i.e. (1) hot tip hot runner system, (2) sprue gating hot runner system and (3) valve gating hot runner system.

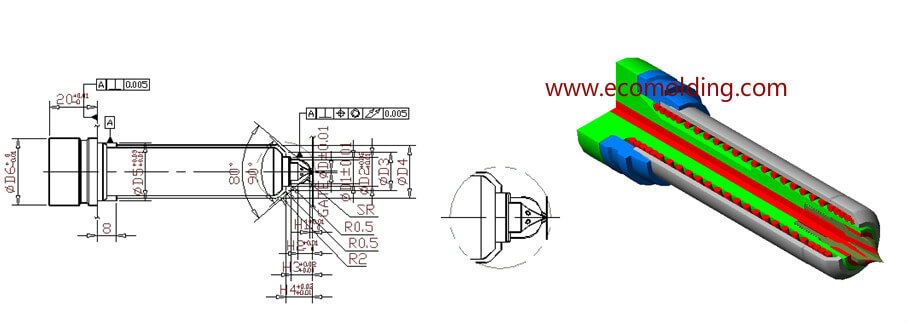

Hot Tip Hot Runner Systems

It is the most widely applied hot runner , since each supplier provides this system. Though systems from different suppliers feature different nozzle and nozzle insert of different shapes and sizes, they work precisely the same way, which is precisely adjusting and controlling the plastic injection molding temperature at the gate through an approach that combines the insert hot tip at the front of the nozzle with the cooling system. As a result, the material and design shape of the nozzle insert hot tip are of great importance. Each hot runner supplier has invested a lot in the R&D of hot tip.

The hot tip hot runner system can be applied to process the majority of crystalline and non-crystalline plastic materials, such as PP, PE, PS, LCP, PA, PET, PBT, PEEK, POM, PEI, PMMA, ABSPVC, PC, PSU and TPU, etc. Generally speaking, the hot tip gate is used to produce medium and small sized parts, esp. suitable for production of micro parts. The sectional diameter of the gate usually measures between 0.5mm and 2.0mm.

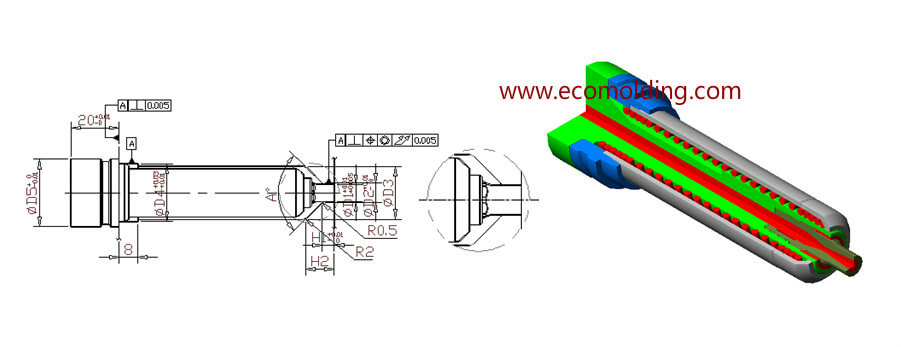

Sprue Gating Hot Runner Systems

In the sprue gating hot runner, the plastic material enters the mold cavity through the smooth open pipe. Melt flow pressure loss in the gate area is slight. The sprue gating hot runner system is more suitable for production of medium and large sized parts. The advantages that the sprue gating hot runner system brings is that the molten plastic undergoes a low shear rate when flowing through the gate, so the molded part will feature a smaller residue stress, leading to a minor deformation rate and a greater mechanical strength of the part. Compared with the hot tip hot runner system, the gate mark might be more visible due to the larger size of the sprue gating. So, the sprue gating hot runner system is usually applied to internal parts or components that do not have high aesthetic requirements on gate appearance. Also, the sprue gating is often used in combination with the cold runner, i.e. taking the sprue nozzle as the main runner, and designing the sprue gating along the cold runner. In the application, the sprue gating can be bigger to facilitate plastic flow, because no one cares about the gate marks on the cold runner.

Valve Gating Hot Runner Systems

The valve gating hot runner is another widely applied hot runner systems that is supplied by global mainstream suppliers. Through the valve pin controller, this system mechanically opens or closes the gate at the pre-set time. This types of hot runner system possesses the advantages beyond the reach of the previous 2 systems (Hot Tip Hot Runner System & Sprue Gating Hot Runner System), such as controlling the gate open/close time manually, allowing a smooth and glossy gate, and expanding the technical scope of hot runner application.