Moldflow analysis is the plastic injection molding simulation software that obtains data and results through the computer-aided simulation to simulate the plastic injection molding process, based on which, the feasibility of the mold solution is to be evaluated, in a bid to improve mold and product designs.

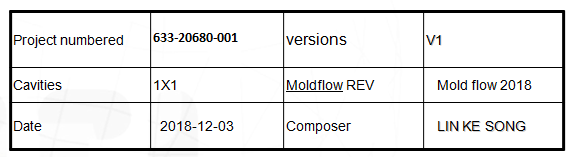

Wall thickness and mesh statistics in moldflow analysis

Thickness are uniformed

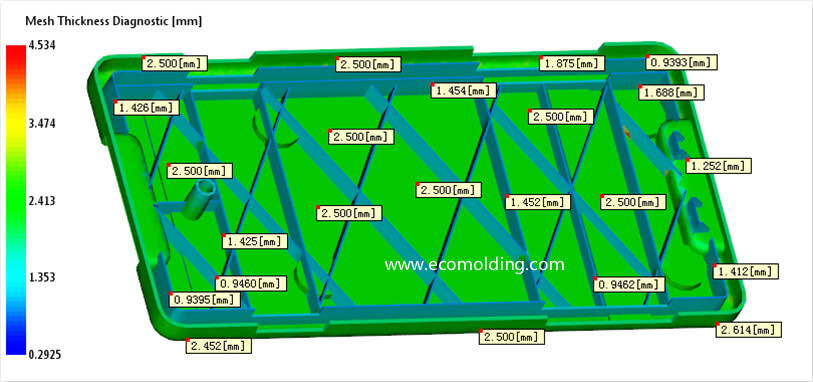

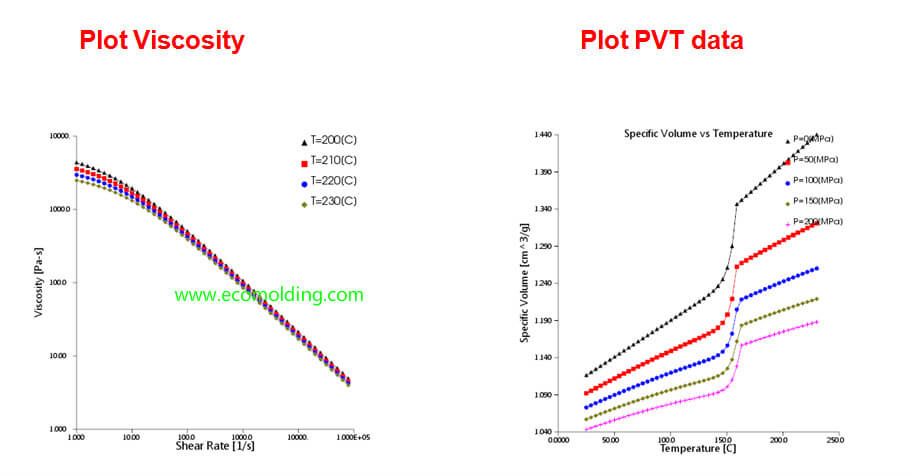

Plastic material information

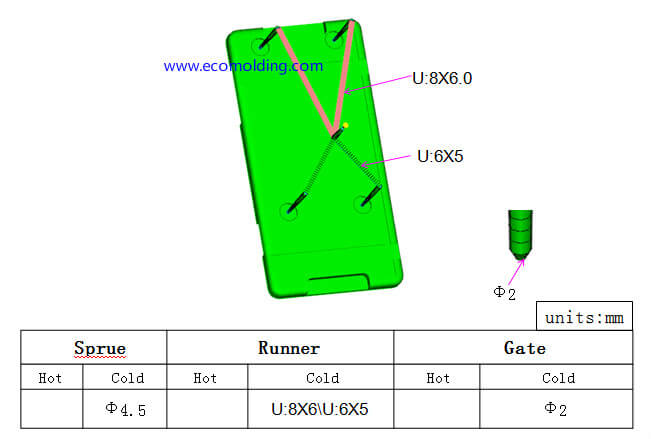

Initial Nozzle/Gate Locations and Circuit

Filling

The filling process is balance

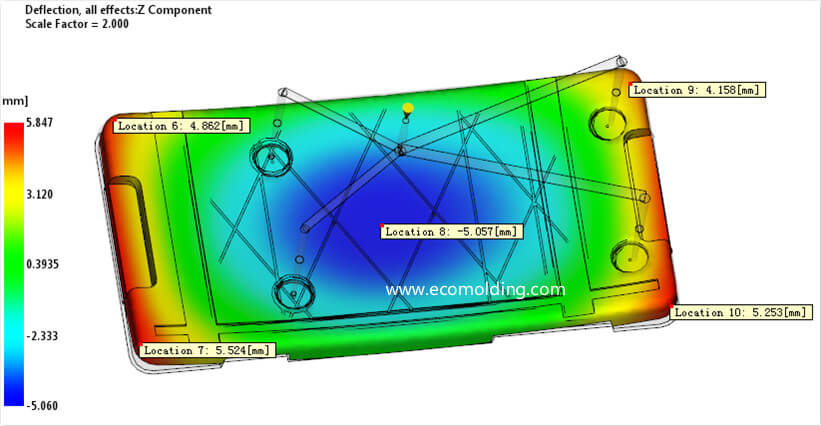

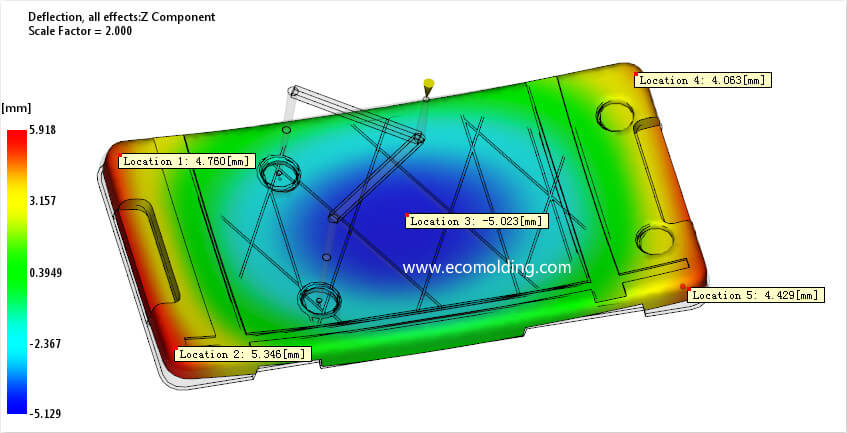

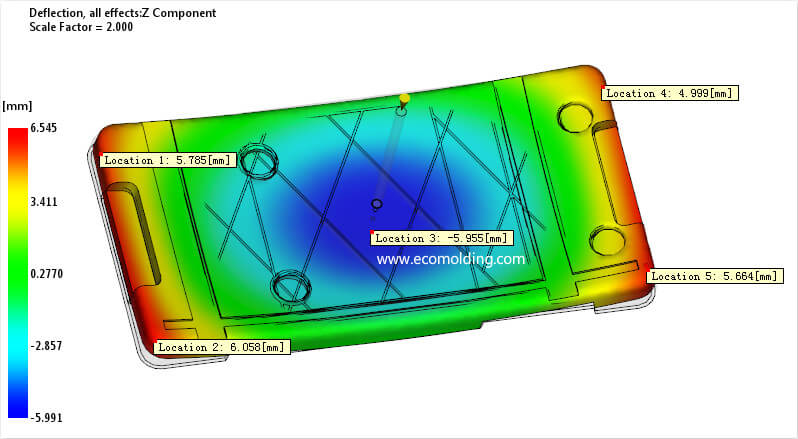

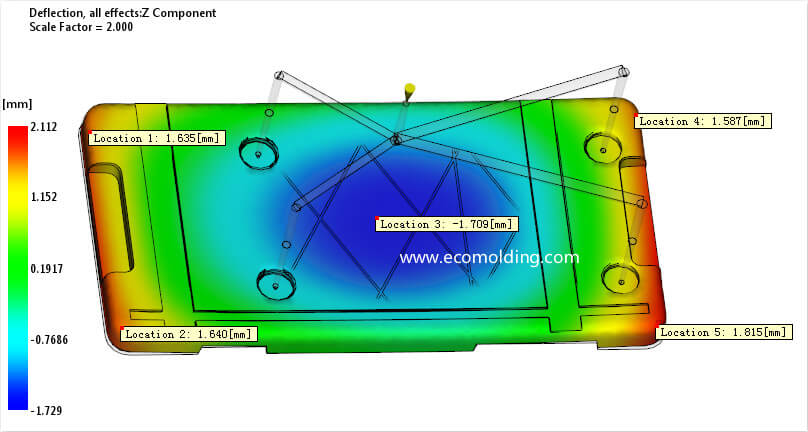

Distortion, all effects at Z Component

In this plot a scale factor of 2X was added to overstate the magnitude of the warpage to make the trends easier to understand。

1) 4 gates injection

Deflection of Z direction is large NG

2)2 gates injection

Deflection of Z direction is large NG

3)One gate hot runner injection

Deflection of Z direction is large NG

4)Change material to ABS Chimei PA757,4 gates

Deflection of Z direction is small OK

Conclusion:

As can be seen from the above results of moldflow analysis, four-point glue injection is smaller than two-point glue injection, but the deformation is not significantly improved. After replacing PP with ABS, the deformation is significantly reduced. It is suggested to use ABS material forming to reduce product deformation.