In the plastic injection molding industry, some newcomers often ask: why the final plastic parts have a higher gloss when the mold temperature is higher. Now in plain language, let’s explain this phenomenon, as well as how to appropriately select the right mold temperatures.

1,Influence on Product Appearance:

First of all, a too low temperature will affect the fluidity of the molten plastic, leading to incomplete filling; mold temperature influences the crystallinity of plastic materials. For ABS materials, if the temperature is too low, the final product will have a lower gloss. Compared with the filler, plastic tends to move to the surface when put under the high temperature condition. Therefore, a higher temperature will allow the plastic to contact with mold surface more closely, thus ensuring better filling, as well as higher brightness and gloss. Yet, the temperature of the plastic injection mold cannot be too high, or sticking to cavity will be caused and bright spots will also appear in some local areas of the plastic part. On the other hand, if the mold temperature is too low, the plastic part will be clamped so tight that it may be damaged during mold release, in particular the surface texture of the plastic part.

Multi-stage injection is able to solve positional problems. For example, we can employ the multi-stage injection approach to solve product gas marks caused during the filling process. In the plastic injection molding industry, the gloss level of a smooth surfaced product will be higher when the mold temperature is high, and verse versa. However, for textured PP products, the higher the temperature, the lower the gloss, and the larger the color difference – the gloss is inversely proportional to the color difference.

As a result, one of the most common problems caused by mold temperature is the rough surface of the plastic injection molded part, which is mainly because the surface temperature of the mold is too low.

2,Influence on Product Dimensions:

If mold temperature is too high, the molten plastic will probably decompose and the shrinkage rate of the plastic product will be larger when exposed to air, leading to shrunk product dimensions. When a mold is used under a low-temperature condition, if product dimensions are increased, the most likely cause is the very low surface temperature of the mold. The reason is that when the mold surface temperature is too low, the molded product will have a lower shrinkage rate when exposed in the air, so the dimensions are larger – the reason being that the low mold temperature will accelerate the molecules “freezing tendency”, creating a thicker frozen layer of the molten plastic inside the mold cavity. At the same time, the low temperature will also impede the crystallization process, therefore the shrinkage rate of the molded product is decreased. On the contrary, higher mold temperature will slow down the cooling process of molten plastic, resulting in a longer relaxation time and a lower level of tendency, while also facilitating crystallization. Thus, the actual shrinkage rate of the product will be higher.

If the startup process is very long before the dimensions stabilize, it means the temperature is not appropriately controlled, because it takes a long time for the mold to reach thermal balance.

Uneven heat radiation at some parts of the mold will greatly extend the production cycle, causing the injection molding cost to rise. A consistent mold temperature is able to minimize the fluctuation of molding shrinkage rate, thus enhancing dimensional stability. For crystalline plastics, a high temperature is helpful for the crystallization process, while a fully crystallized plastic part is subject to minimal dimensional changes during storage or application. However, the higher the crystallinity, the higher the shrinkage rate. For soft plastic materials, a low mold temperature is recommended in the molding process, which is helpful for dimensional stability. For all the materials, it is true that consistent mold temperatures and shrinkage rate are helpful for improvement of dimensional accuracy.

3. Influence on Product Deformation:

If the mold cooling system is not reasonably designed or the mold temperature is not appropriately controlled, part warpage will be caused due to insufficient cooling. To ensure proper mold temperature control, the temperature difference between the cavity side and the core side should be defined on basis of the structural characteristics of the plastic product. We can offset the shrinkage differences caused by molecular orientation and therefore avoid orientational part warpage by controlling the different cooling and shrinkage speeds at different parts of the mold while also considering the characteristic that the part tends to warp towards the side where the temperature is higher after mold release.

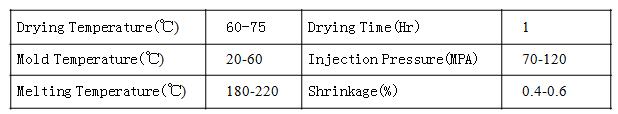

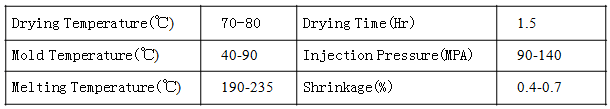

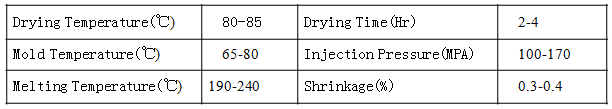

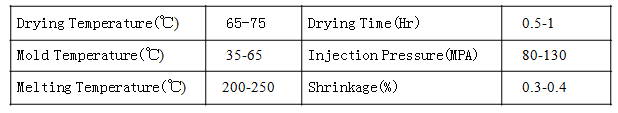

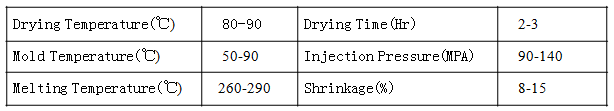

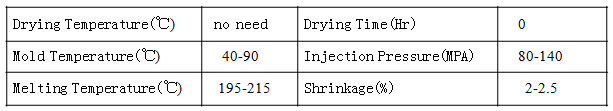

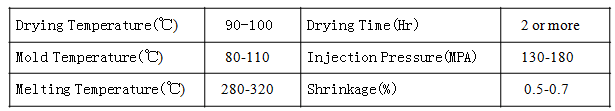

For fully symmetrical parts, the mold temperature should be kept consistent to guarantee cooling balance within the entire part. A consistent mold temperature and balanced cooling is able to minimize part deformation. On the contrary, if the mold temperature difference is too large, uneven part cooling will be caused, leading to inconsistent shrinkage, and the internal stress thus caused will make the plastic part warp. This is especially true for plastic parts with an uneven wall thickness and a complicated shape. The product will definitely warp towards the mold side where the temperature is higher. It is suggested that the temperatures of the cavity side and the core side should be properly selected depending on actual needs. Please refer to the Material Property Table for mold temperatures.

4,Influence on Product Mechanical Properties (Internal Stress):

A low mold temperature will lead to obvious welding lines on the plastic part, which reduces the product strength; with regard to crystalline plastics, the higher the crystallinity, the more likely stress cracks will appear on the plastic product. To reduce internal stress, the mold temperature should be kept at a moderate level (PP, PE). As for the amorphous plastic materials like PC which possess a high stickiness, the stress cracks are associated with the internal stress of the plastic part. So, it will help reduce internal stress by raising mold temperature, so as to reduce the tendency towards stress cracks. The internal stress is usually indicated by obvious stress marks.

The reason is: basically, the internal stress occurring in a molding process is caused by the different thermal shrinkage rates during cooling. After the plastic product is molded, cooling will take place and extend from the surface to the core. The surface shrinks and solidifies first, and then gradually extending to the inside. During this process, the internal stress is caused due to the difference in shrinkage speed. When the residual stress inside the part is higher than the elasticity of the resin material or the part is corroded in a chemical environment, cracks will appear on the part surface.

The research into the PC and PMMA transparent resin materials indicates that, the residual stress shows a contracted form on the surface layer but a stretched form on the inside. The compressive surface stress is dependent on the surface cooling conditions. A cold mold is able to cool down the molten resin in a very fast way, so that a high level of residual stress is produced in the molded product. Mold temperature is one of the fundamental conditions for internal stress control. A slight change in mold temperature may make a great difference to residual stress. Generally speaking, the acceptable internal stress of each product and resin material has its lowest limit. When molding a thin-walled product or the flow distance is long, the lowest mold temperature should be higher than that applied to common molding.

5,Suggestions on How to Identify the Right Mold Temperatures:

Nowadays, molds are becoming more and more complex. As a result, it is getting harder for us to create appropriate conditions for mold temperatures control. In addition to simplifying the part, the mold temperatures control system is usually a compromise solution. Therefore, the following suggestions only serve as a rough guide.

During the mold design phase, temperature control of the molded part must be taken into consideration. For example, when designing a low-volume large-size plastic injection mold, one of the most important considerations is the cooling performance. Concerning the molds for production of precision parts, or of the parts that have to meet stringent appearance or certain safety standards, a higher temperature is usually applied (ensuring lower shrinkage rate, glossier surface and consistent performance). For parts that require lower technologies and minimal production costs, a lower temperature should be applied during the molding process. Nevertheless, manufacturers should be aware of the respective weaknesses of the choices and perform careful inspection of the parts, to make sure that the produced parts are still able to satisfy customer requirements.