Warpage as one of the most common defects in a plastic injection molded product, refers to the situation in which the shape of the injection molded part deviates from the shape of the mold cavity. The following is a brief analysis of the factors that affect the warpage of the injection molded products.

How the mold structure influences the warpage of an injection molded product

With regard to the mold, the main factors that affect the deformation of a plastic part are the gating system, the cooling system and the ejection system

Gating System

The gate location, type and quantity of a plastic injection mold affect the filling status of the plastic in the mold cavity, leading to changes to the plastic part. For some flat plastic parts, if only one central gate is employed, the molded plastic part will be distorted, as the shrinkage rate along the diameter is greater than that along the circumference; if multiple pin-point gates or the film gate is used, product warpage defects can be effectively prevented.

During the plastic injection molding process, the ununiform cooling rate of the plastic part will also cause ununiform shrinkage in the part, which leads to the generation of the bending moment, and therefore warpage of the plastic injection molded part.

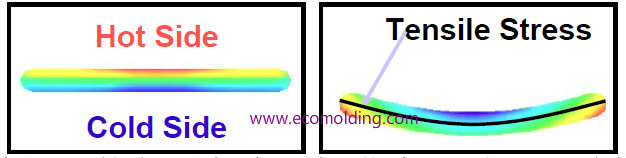

During the plastic injection molding of a flat plastic part (such as the mobile phone battery case), if the temperatures in the mold cavity and the core differ greatly, the molten plastic close to the surface of the cold mold body is quickly cooled down, and that close to the surface of the hot mold cavity continues to shrink. Such an ununiform shrinkage will cause part warpage. In addition to considering the temperature balance inside and outside the plastic part, it also needs to be ensured that the temperature on each side of the plastic part is consistent, i.e., during mold cooling, the temperatures of mold core and the mold cavity should be kept as consistent and uniform as possible, so that an uniform cooling rate throughout the plastic part is ensured to effectively prevent the occurrence of warpage.

Ejection System

The design of the ejection system also directly affects the warpage of a plastic injection molded part. If the ejection system is not designed with a balanced layout, it will cause an imbalance in the ejection force, which leads to plastic product warpage. The cross-sectional area of the ejector pin should not be too small, so as to prevent the plastic part from being deformed by excessive force per unit area (especially when the temperature is too high during ejection). The ejector pins should be placed as close as possible to the area with a large ejection resistance.

How plasticization process influences product warpage

Plasticization refers to the process in which the plastic is converted from vitreous granules into a viscous melt. During this process, the temperature differences of the polymer along the axial and the radial directions (relative to the screw) will cause stress in the plastic material; in addition, the injection pressure, speed and other parameters of the injection molding machine have a great impact on the degree of molecular orientation during plastic filling, which causes warpage, or deformation.

How plastic filling and cooling influence product warpage

The effect of temperature on product warpage is reflected in the following aspects:

- The temperature difference between the upper and lower surfaces of the plastic part may cause thermal stress and therefore thermal deformation;

- The temperature difference between different areas of the plastic part will cause uneven shrinkage between different areas;

- Different temperature conditions influence the shrinkage of a plastic part.

How product ejection influences product warpage

The imbalanced ejection force, unsteadiness in the movement of the ejection mechanism, or the inappropriately designed ejection area easily causes product deformation . At the same time, the stress that is “frozen” in the plastic part during the filling and cooling processes will be released in the form of “warpage” due to the loss of external constraints, resulting in product deformation.

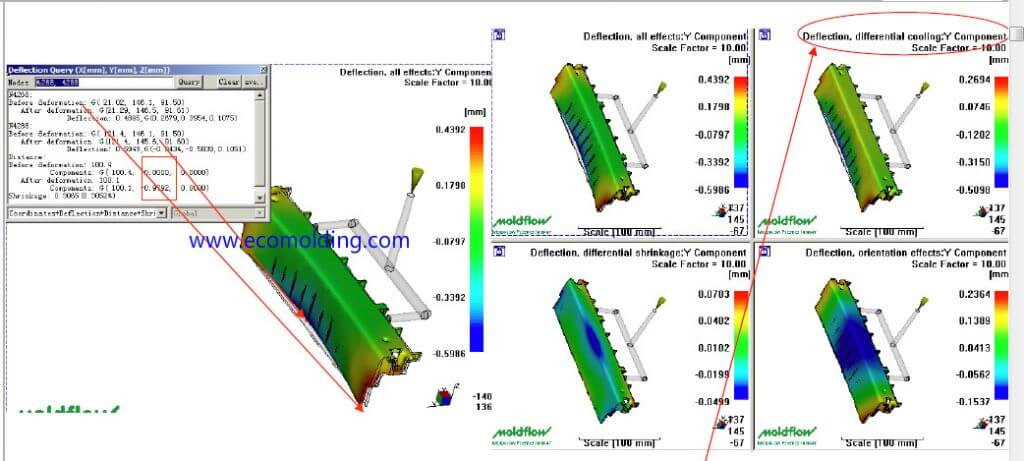

How product shrinkage influences product warpage

The immediate cause of warpage defects of an injection molded product is the uneven shrinkage of the product. If the influence of shrinkage during the filling process is not taken into consideration during the mold design stage, the geometry of the product will vary greatly from the design requirements. For warpage analysis, shrinkage itself is not important, but what is important lies in the shrinkage difference.

How residual thermal stress influences product warpage

During the plastic injection molding process, residual thermal stress is an important factor that causes product warpage, and thus exerts a great influence on the quality of an injection molded product. Since the influence of residual thermal stress on product warpage is very complicated, it will not be detailed here.

How the metal insert influences product warpage

With regard to plastic injection molded products with inserts, it is easy to cause distortion (even cracking), since the shrinkage of plastic is much higher than that of metal; to improve this, the metal part needs be preheated (generally at a temperature of no lower than 100°C), before being put into production.

Conclusion

There are many factors that affect the warpage defects of an injection molded product. The structure of the mold, the thermophysical properties of the plastic material, as well as the conditions and parameters of the molding process all exert different influences on the product warpage defects. Therefore, when handling the warpage of a molded product, we must take all the above factors into consideration.